RFID Tool Warehouse Solution

Applicable scenarios: machinery manufacturing plants, precision processing workshops, home appliance manufacturing enterprise maintenance rooms, automobile repair shops, commercial vehicle/engineering vehicle service stations, power plant maintenance rooms, wind power, photovoltaic maintenance teams, power company distribution maintenance warehouses, aircraft maintenance warehouses, ship repair shops, heavy equipment maintenance bases, large construction site tool warehouses, construction enterprise equipment rooms, tunnel, bridge construction and maintenance teams, hospital engineering maintenance departments, etc.

1. Industry Challenges

Managing tools in maintenance-driven sectors like manufacturing or engineering often turns into a daily struggle. Counting tools by hand is slow and mistakes happen easily, especially when you’re dealing with hundreds of small items. Tools also tend to disappear or end up in the wrong place, and without real tracking, it’s hard to hold anyone accountable. Most companies still rely on sign-in sheets for entry and exit, which don’t really prevent unauthorized removal. Another pain point is visibility—you rarely know where a tool is or who has it, which means duplicate purchases and delays. Finally, compliance checks and audits become a headache when everything is recorded manually.

2. How RFID Solves This

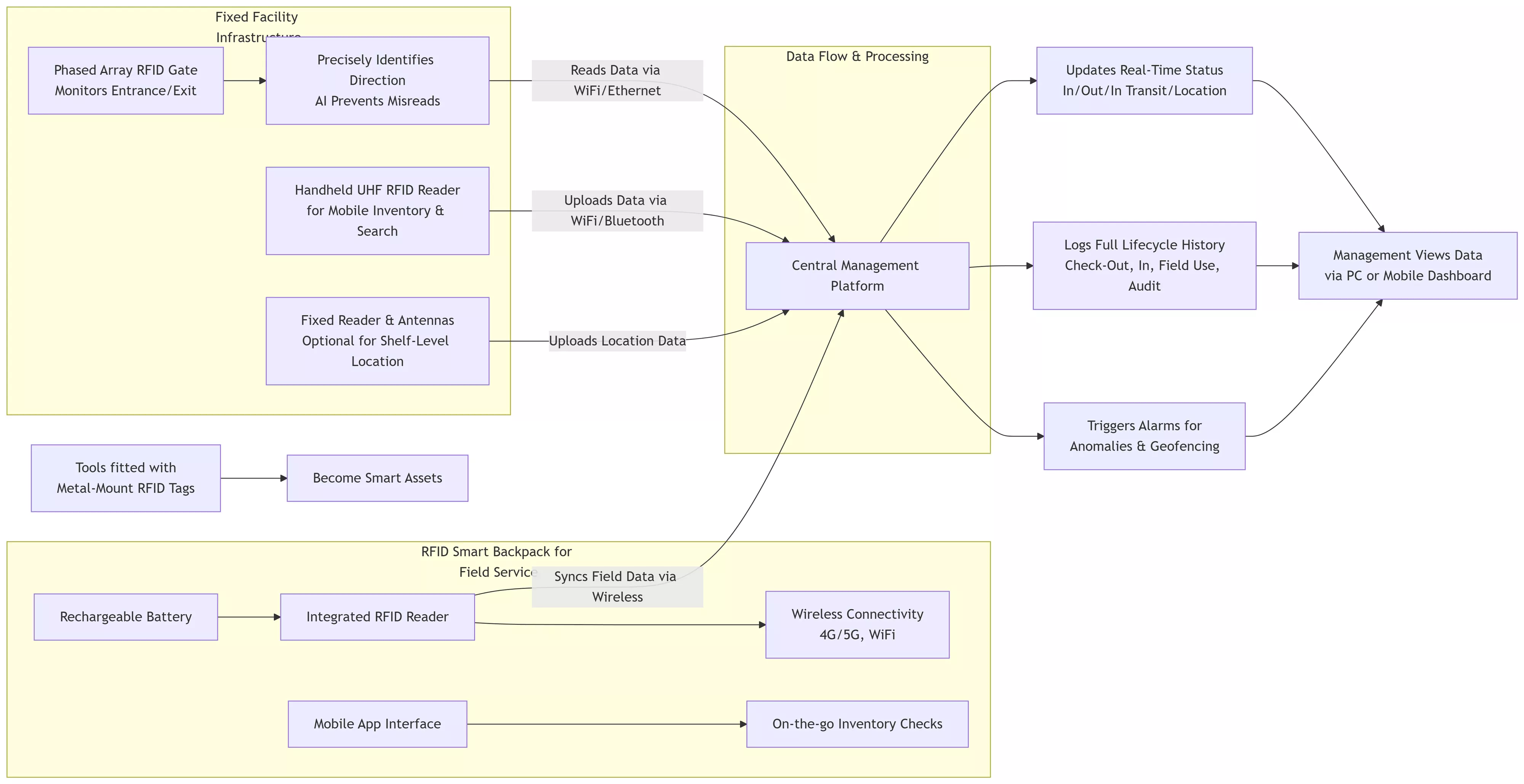

Our solution combines several technologies to simplify tool control: RFID Gate (AI algorithm + phased array), RFID Metal Tags, Handheld Reader, Portable RFID Reader, RFID Smart Tool Kit, and an RFID Label Printer. Together, they create a system that does the heavy lifting for you:

You can register and count tools in batches instead of one by one, which saves hours

The RFID Gate uses phased-array antennas with AI to accurately detect movement and cut down on errors like missed or false reads

Every borrow or return updates in real time, so you always know what’s in stock and what’s out

Alerts kick in when a tool isn’t returned or leaves without authorization

For larger storerooms, optional fixed readers and antennas let you track tools down to the shelf level

Built-in reporting shows usage patterns and helps you plan purchases smarter

For field work, the RFID Smart Tool Kit makes it easy to keep control when your team is working off-site

3. Recommended Components

RFID Gate (AI algorithm + phased array technology)

Placed at entry points to capture tool movements with precision

RFID Metal Tags

Designed for metal tools—rugged, waterproof, and long-lasting

Handheld RFID Reader

Best for quick audits or spot checks, with wireless connectivity

Portable RFID Reader (Smartphone Plug-in)

Compact and easy to use, ideal for small tools and mobile scans

RFID Smart Tool Kit

Includes a reader, power bank, pre-tagged labels, and a mobile app for off-site jobs

RFID Label Printer

For fast and easy tag printing when adding new tools

Fixed RFID Reader + Antennas (Optional)

Gives shelf-level visibility for larger or high-security storage areas

4. Management Process

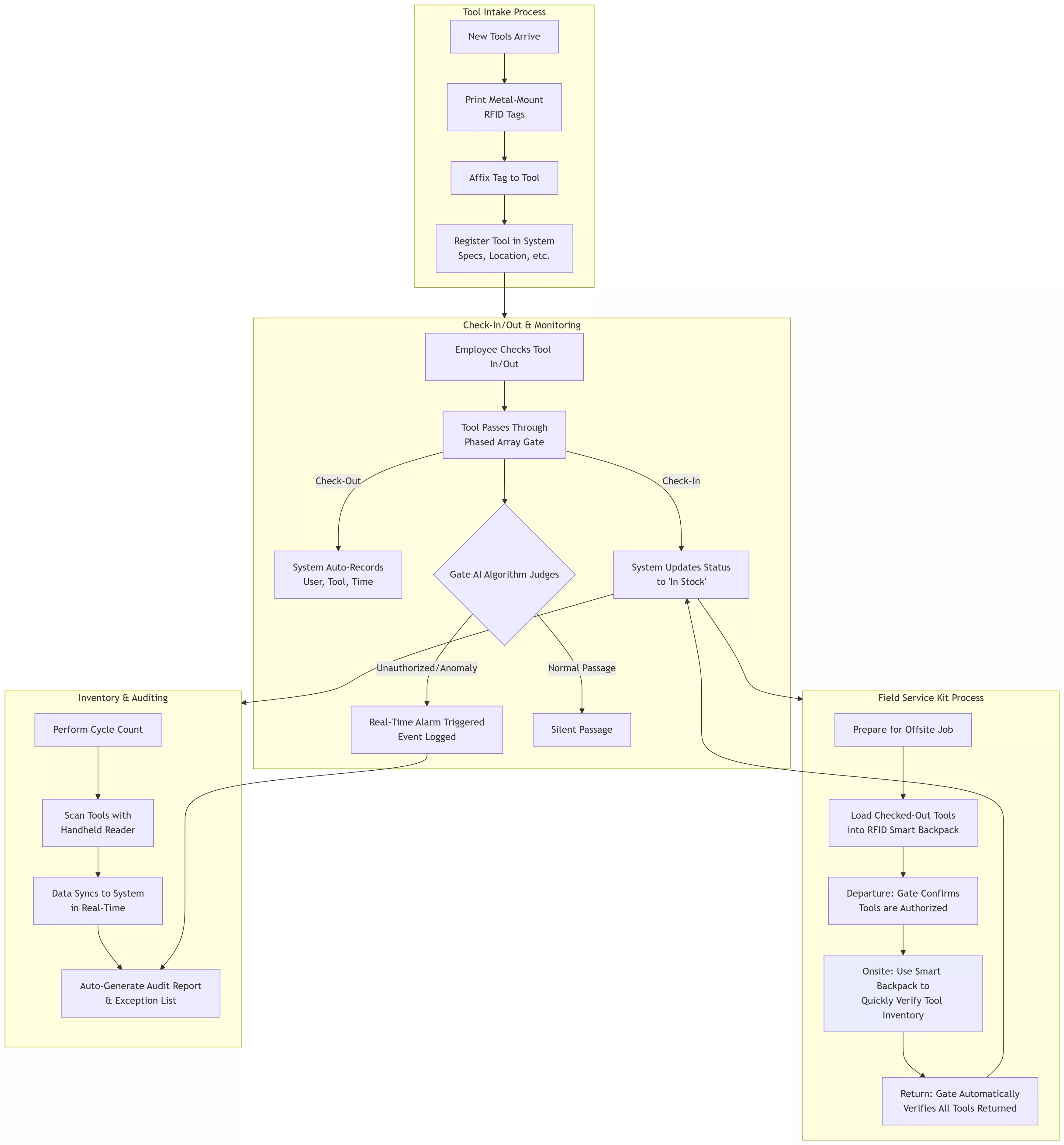

Tagging new tools – Print, attach, and register in the system

Borrow and return – Tools pass through the gate, and status updates automatically

Inventory checks – Use handheld or portable readers for fast batch scans and instant reports

Access control – The gate detects any unauthorized movements and sends alerts

Field service – The Smart Tool Kit keeps borrowed tools under control during off-site work

Location tracking – Optional fixed readers show exact positions inside the storeroom

5. Why It Matters

Cut inventory time by up to 80%

Reduce tool loss and misuse through real-time control

Always know who has what, and where it is

Stay compliant with full traceability for audits

Scales easily for small and mid-sized businesses

Data-driven insights for better planning

Contact us for a quote on our RFID Tool Warehouse Kit