What Are the Main Types of RFID Tags?

If you’ve ever wondered why some RFID tags survive harsh factory environments while others are used in delicate retail packaging, you’re not alone. RFID tags come in many forms — each designed to balance range, durability, and cost for different use cases.

At RFID Reader.io, we’ve worked with integrators and developers who often ask which tag type is best for their projects. The truth is: it depends on where and how the tag will be used.

1. Passive RFID Tags

Passive tags are the most common type. They have no internal power source and rely on the electromagnetic energy from an RFID reader’s signal to operate.

Because they’re thin, affordable, and durable, they’re ideal for large-scale tracking like inventory control, asset identification, or retail tagging.

- Frequency ranges: LF (125–134 kHz), HF (13.56 MHz), UHF (860–960 MHz)

- Best for: Supply chain tracking, library systems, apparel, and packaging

- RFID Reader.io products: We provide high-performance UHF passive tags designed for both paper labels and on-metal use.

2. Active RFID Tags

Active tags include a built-in battery, allowing them to broadcast signals independently of the reader.

They have a longer read range — sometimes up to hundreds of meters — and are used in high-value or moving asset tracking applications.

- Best for: Vehicle tracking, equipment management, container logistics

- Power source: Internal battery (replaceable or sealed)

- RFID Reader.io insight: Our partners in logistics often combine active tags with fixed long-range readers for yard or gate monitoring systems.

3. Semi-Passive (Battery-Assisted) RFID Tags

A semi-passive tag has a small battery that powers its chip but still relies on the reader’s signal to communicate.

This type bridges the gap between passive affordability and active performance.

- Best for: Cold-chain monitoring, sensitive goods, and temperature logging

- Example: RFID Reader.io offers battery-assisted UHF labels for refrigerated transport, helping integrators collect both ID and condition data in one scan.

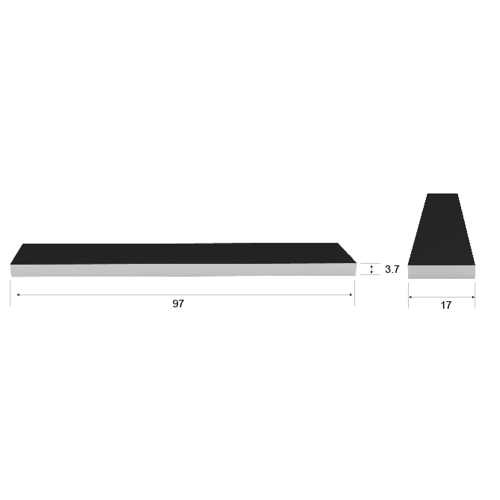

4. On-Metal RFID Tags

Metal surfaces can interfere with radio waves, but on-metal tags solve that problem.

They include a special insulating layer or magnetic material that reduces interference, allowing accurate reads on metal shelves, tools, or machinery.

- Best for: Industrial tools, equipment, and automotive parts

- Why choose: High read accuracy even in harsh or metallic environments

- RFID Reader.io advantage: Our flexible on-metal tags combine adhesive backing and heat resistance for reliable attachment.

5. Flexible and Textile RFID Tags

Modern applications call for flexible, washable tags — especially in clothing and uniforms.

These soft tags are often embedded in fabric or silicone for durability.

- Best for: Laundry tracking, rental textiles, fashion retail

- RFID Reader.io lineup: We provide textile-friendly HF and UHF tags that can withstand repeated washing and ironing.

6. Special-Use RFID Tags

Certain industries demand specialized tags for challenging environments — from chemicals to outdoor exposure.

- Examples:

- High-temperature tags for paint shops and foundries

- Tamper-evident tags for asset protection

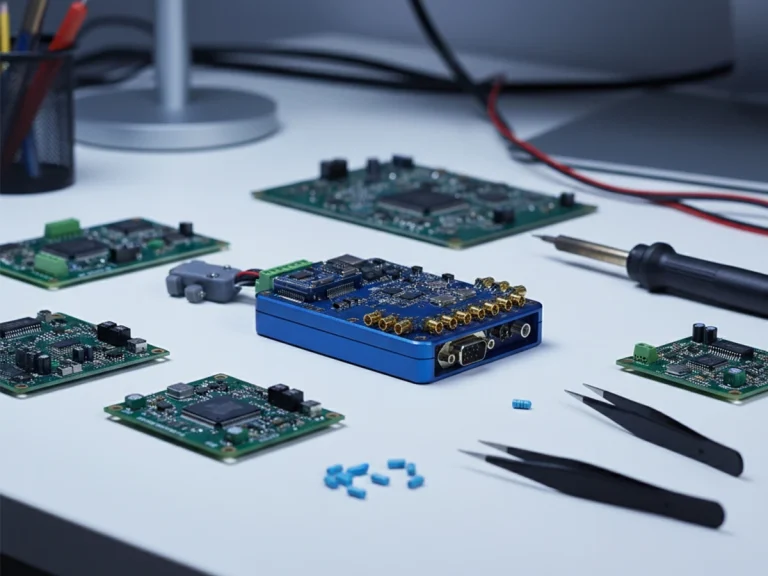

- Miniature tags for medical or electronic components

RFID Reader.io works with OEMs to produce custom-encoded and form-fitted RFID tags that match exact project needs.

Choosing the Right Tag

When selecting an RFID tag, consider three main factors:

- Surface type: metal, plastic, cardboard, or textile

- Reading distance: short, mid, or long range

- Environment: indoor, outdoor, high temperature, or wet areas

Integrators often run pilot tests using RFID Reader.io evaluation kits, pairing our tags with matching readers and antennas for optimal results.

FAQ

Q1: What’s the difference between passive and active RFID tags?

Passive tags rely on the reader’s energy, while active tags have their own battery and transmit over longer distances.

Q2: Can I use the same RFID tag for metal and non-metal surfaces?

Not always. Metal can detune the antenna, so use an on-metal tag for metallic objects.

Q3: Are RFID tags reusable?

Yes, many UHF and HF tags can be reprogrammed, especially when used with readers from RFID Reader.io.

Q4: How long do RFID tags last?

Passive tags can last up to 10 years; active tags depend on battery life (2–5 years on average).

Q5: Can I customize tag shape or encoding?

Absolutely. RFID Reader.io offers OEM/ODM services to tailor tag dimensions, encoding, and form factor.