How to Integrate RFID Antennas with Fixed Readers for Optimal Coverage

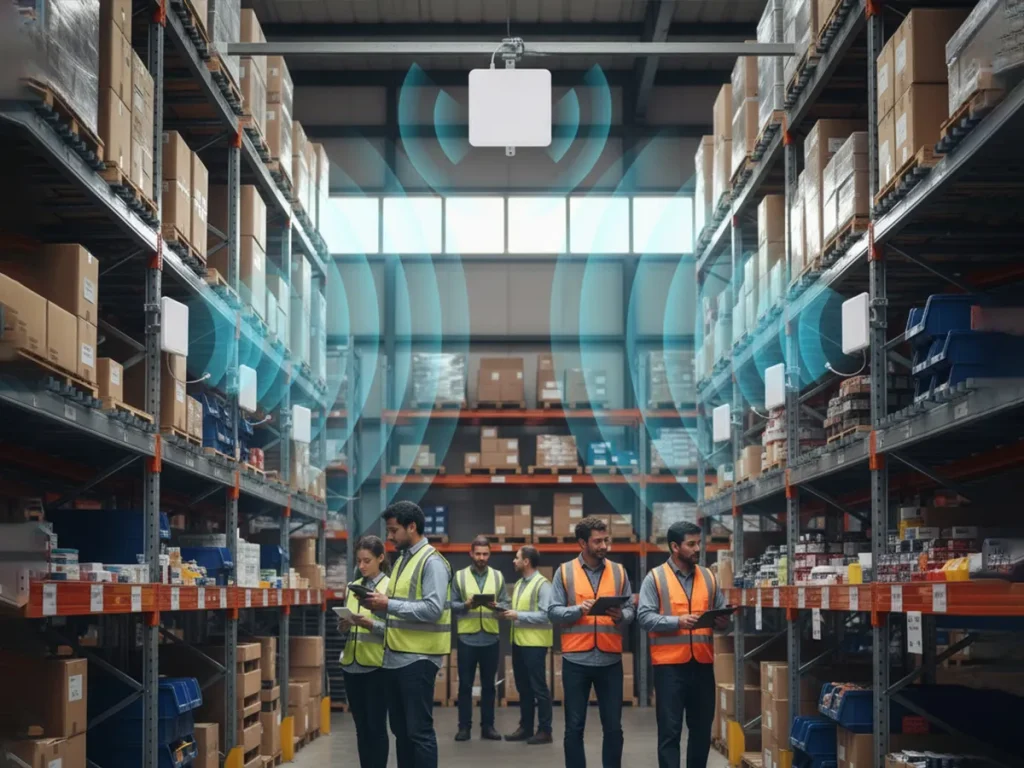

Ensuring complete RFID coverage in a warehouse or logistics facility is rarely as simple as just mounting a reader. The reader is only part of the system—without properly positioned RFID antennas, you risk blind spots, missed scans, or inconsistent performance.

Take a mid-sized distribution center I recently visited. They had installed fixed readers but were still missing inventory reads at the far end of the warehouse. By carefully analyzing the floor plan and adjusting RFID antennas placement, they achieved full coverage, drastically reducing errors in daily inventory counts.

Why RFID Antennas Matter

- Signal Directionality: Antennas determine where the reader can “see.” Without proper alignment, tags in certain areas may never be read.

- Distance Control: Different antennas offer varying ranges. Long-range antennas are ideal for loading docks, while compact antennas work well for tight shelving areas.

- Interference Management: Metals, liquids, and other RFID tags can interfere. Selecting antennas with proper polarization and placement minimizes these issues.

Steps to Optimize Coverage

- Plan your layout: Map your facility and identify high-traffic or critical areas. Determine how many antennas you’ll need for each zone.

- Select compatible antennas: Ensure your antennas match your fixed readers in frequency, gain, and polarization. RFID Reader.io provides antennas optimized for different industrial environments.

- Mount strategically: Position antennas to cover entire aisles, entry points, or docking areas. Avoid placing them too close to metal surfaces unless using metal-resistant models.

- Test coverage: Walk the warehouse or facility with sample tags to verify read consistency. Adjust angles or height as needed.

- Monitor and fine-tune: Even after installation, periodically test to ensure performance remains reliable as inventory, racks, or shelving configurations change.

Real-Life Observations

In one warehouse, simply changing the angle of a few antennas improved tag reads by over 30%. Another facility integrated RFID Reader.io antennas with their fixed readers, and staff reported fewer missed items during shift change audits.

Key Takeaways

- Proper antenna selection and placement is as important as the reader itself.

- Even minor adjustments in angle, height, or polarization can significantly improve coverage.

- Combining expertise with robust hardware like RFID Reader.io ensures accurate and reliable RFID tracking.

FAQ – RFID Antenna Integration

Q1: Why do I need multiple antennas for a fixed reader?

To cover all areas of interest and eliminate blind spots, multiple antennas may be required depending on layout and read range.

Q2: Can the wrong antenna affect read accuracy?

Yes. Wrong gain, polarization, or placement can lead to missed scans and inconsistent data.

Q3: How do I test coverage?

Walk the facility with sample tags, check read success, and adjust antenna angles or placement accordingly.

Q4: Are there antennas suitable for metal-heavy environments?

Yes. RFID Reader.io offers antennas designed to minimize interference from metal shelving or machinery.

Q5: Can antennas be mounted outdoors?

Certain models are rated for outdoor use; check for temperature and weather resistance.

Q6: Do antenna adjustments require technical expertise?

Some basic knowledge helps, but many facilities can rely on guidelines and testing to optimize coverage.

Q7: Can one reader handle multiple antennas?

Yes. Fixed readers often support multiple antennas, which allows broader coverage without adding extra readers.

Q8: How often should I review antenna placement?

Whenever facility layouts change or if read accuracy drops, it’s a good idea to re-evaluate antenna placement.

Send Us An Email

Feel free to send us an email and we will reply to you as soon as possible.