Choosing the Right Handheld Terminal for Your RFID Application

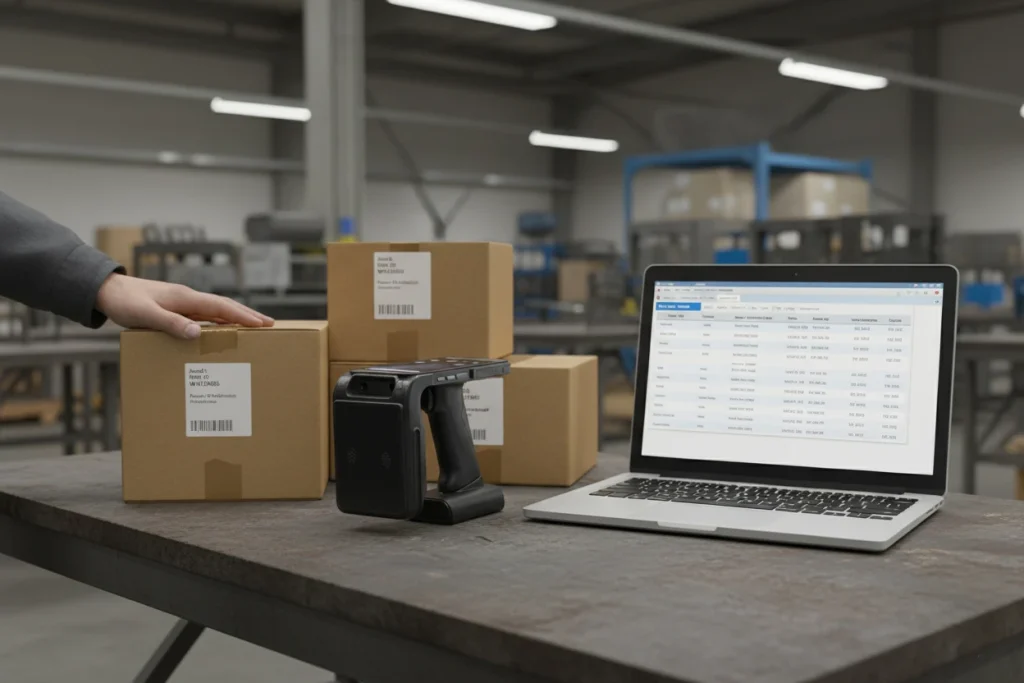

Selecting the right RFID Handheld Terminal is not just about finding a portable device that can read tags — it’s about choosing the right tool that fits your workflow, data environment, and long-term operation goals.

From warehouse operations and field logistics to retail inventory or medical asset tracking, the right handheld terminal can greatly impact efficiency, accuracy, and system reliability.

At RFID Reader.io, we design Handheld Terminals that balance power, ergonomics, and flexibility, ensuring they meet both industrial and commercial demands.

Let’s explore what really matters when choosing the one for your RFID project.

1. Frequency Compatibility

Before anything else, check if the terminal supports the correct RFID frequency for your region and tags.

Most global UHF RFID Handheld Terminals operate on 902–928 MHz (for the Americas) or 865–868 MHz (for Europe and parts of Asia).

Using the wrong frequency means reduced read range or even complete incompatibility.

Tip: If your business operates globally, choose a multi-frequency Handheld Terminal — it ensures compliance and saves you from hardware reconfiguration later.

2. Reading Range and Antenna Design

A terminal’s performance largely depends on its antenna and reader module.

Short-range models are ideal for retail counters or libraries, while long-range versions can reach 6–10 meters, suitable for logistics or asset tracking in open spaces.

RFID Reader.io’s latest terminals use circularly polarized antennas, reducing tag orientation issues and improving read consistency — a crucial factor when scanning fast-moving or randomly positioned items.

3. Processing Power and OS Integration

A modern RFID Handheld Terminal should do more than read tags — it should process, filter, and send data to your ERP or WMS in real time.

Android-based terminals are now the industry standard, offering better app compatibility, integration with cloud services, and faster updates.

Our RFID Reader.io RHT Series runs Android 13 with octa-core processors and up to 8GB RAM, ensuring smooth multitasking for demanding field applications.

4. Connectivity Options

Wireless communication defines how efficiently your RFID terminal interacts with your system.

Look for models that support Wi-Fi 6, 4G/5G, and Bluetooth 5.2.

In remote areas, offline batch mode is also essential — allowing data storage even without a network, then syncing automatically once connected again.

5. Durability and Ergonomics

Industrial users often underestimate how much design affects productivity.

If your staff works long hours scanning pallets or moving between locations, a lightweight, well-balanced terminal can reduce fatigue significantly.

For harsh environments, choose a device with IP65 or IP67 protection, and tested drop resistance beyond 1.5 meters.

6. Battery and Maintenance

Downtime kills productivity.

High-capacity batteries (≥6000mAh) can sustain a full shift of intensive scanning.

RFID Reader.io’s handheld terminals feature hot-swappable batteries, allowing quick replacements without rebooting — a key advantage in logistics or 24-hour operations.

7. Software Ecosystem and SDK Support

Hardware is only half the story.

A reliable SDK ensures your team can easily integrate the terminal into your existing platforms.

Our RFID Reader.io Developer Kit provides ready-to-use APIs for Android and Windows, supporting rapid deployment for both commercial and industrial projects.

8. After-Sales and Scalability

Finally, consider long-term support.

A good RFID Handheld Terminal vendor should offer firmware updates, spare parts availability, and technical assistance.

At RFID Reader.io, we design every product line to scale — so you can expand from pilot stage to full deployment without hardware mismatches.

Conclusion

Choosing the right RFID Handheld Terminal is a long-term investment in efficiency, data accuracy, and operational continuity.

By considering performance, integration, and usability together, you can ensure the device doesn’t just work — it works for your workflow.

RFID Reader.io offers a complete portfolio of professional-grade terminals, designed for logistics, warehousing, healthcare, and retail.

Each model is built for real-world reliability — because in RFID operations, every read counts.

FAQ

1. What’s the difference between an RFID Handheld Terminal and a mobile reader?

A Handheld Terminal integrates an RFID reader, antenna, and computer in one unit, whereas mobile readers usually connect to a phone or tablet via Bluetooth or cable.

2. Can Handheld Terminals read barcodes as well?

Yes. Most RFID Reader.io terminals include both RFID and barcode scanning, allowing seamless hybrid use.

3. How long does the battery last on average?

Typically 8–12 hours of continuous use, depending on screen brightness and data transmission.

4. Do I need a special app to use it?

You can use RFID Reader.io’s built-in demo app, or develop your own using our SDK and APIs.

5. Are these terminals suitable for outdoor environments?

Yes. Our IP-rated terminals are built to handle dust, rain, and temperature variations.

6. How many RFID tags can a Handheld Terminal read at once?

That depends on the reader module and antenna design, but most industrial RFID Handheld Terminals can process 100–200 tags per second under good conditions. In practice, factors like tag density, metal surfaces, and movement speed affect the count more than the reader itself.

7. Can I connect the Handheld Terminal directly to my company’s ERP or WMS?

Yes. Most RFID Reader.io Handheld Terminals support API-based and SDK-level integration with popular enterprise platforms such as SAP, Oracle, and custom-built systems. In some setups, you can even push data directly via MQTT or RESTful APIs without middleware.

8. What kind of maintenance does an RFID Handheld Terminal need?

Aside from regular charging and software updates, maintenance is minimal. Occasionally cleaning the antenna area and the barcode window (if included) helps maintain accuracy. For industrial users, a periodic firmware check keeps the device running efficiently.

9. How secure is the data collected through a Handheld Terminal?

Security depends largely on how your network handles it. RFID Reader.io devices use encrypted data transmission (HTTPS, TLS) and optional user authentication to prevent unauthorized access, ensuring compliance with enterprise-grade data protection policies.

10. Can multiple Handheld Terminals operate in the same area without interference?

Yes — most models use anti-collision algorithms that prevent overlapping reads. However, it’s good practice to assign logical zones or timing offsets when deploying several terminals in a confined space, especially in dense tag environments.

11. What’s the typical lifespan of a professional RFID Handheld Terminal?

Usually between 3 to 5 years, depending on daily usage and environment. Rugged industrial-grade models often last longer, especially when batteries and key components are replaceable.

12. Are RFID Handheld Terminals suitable for asset tracking in healthcare or labs?

Absolutely. Many hospitals use handheld terminals to track equipment, medication trays, and lab samples. Since most devices support both HF and UHF RFID, they can handle various tag types used in sensitive indoor environments.

13. Can I customize the user interface or add my own applications?

Yes. All RFID Reader.io terminals run on open Android systems, allowing you to install, modify, or develop apps that match your workflow. Developers can create specialized scanning layouts, automated tag filters, or custom dashboards.

14. Do RFID Handheld Terminals require a constant internet connection?

No. They can operate offline in batch mode, storing reads locally and syncing once a network becomes available. This is essential for field inspections or outdoor inventory tasks where connectivity is limited.

15. How do I know if I need a Handheld Terminal or a Fixed Reader setup instead?

It depends on mobility. If your staff moves around, scanning across different zones or vehicles, a Handheld Terminal is ideal. For static locations like dock doors or conveyor lines, a Fixed Reader system offers higher throughput and less manual work.

Send Us An Email

Feel free to send us an email and we will reply to you as soon as possible.