How to Integrate RFID Tags into Inventory Tracking Systems

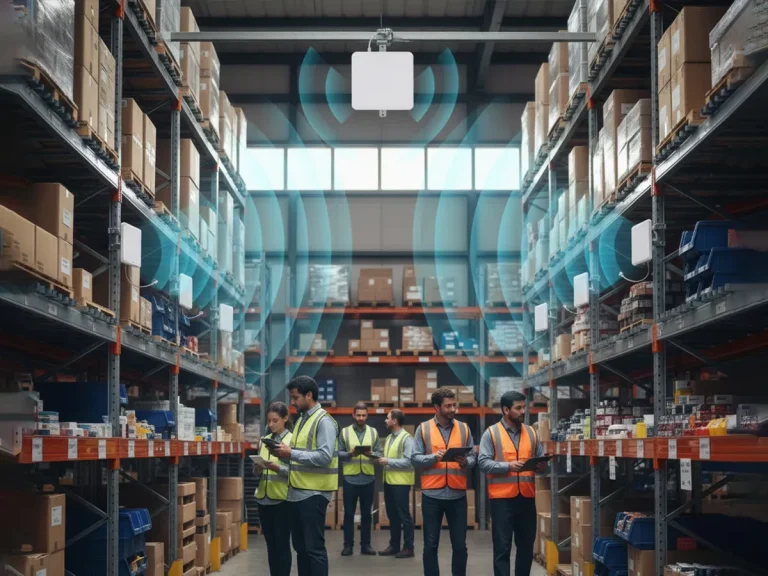

If you’ve ever tried to keep a busy warehouse organized using spreadsheets or barcode scanners, you know how messy it can get. Items get misplaced, counts are off, and staff spend hours double-checking numbers. That’s why many logistics and retail operations are switching to RFID tags for inventory tracking.

I recently worked with a mid-sized warehouse that had been struggling with daily stock discrepancies. They implemented RFID Reader.io tags and handheld readers at key locations. The difference was immediate: scans that used to take hours could be done in minutes, and inventory accuracy improved noticeably.

Why RFID Tags Make a Difference

Unlike barcodes, RFID tags don’t need line-of-sight. You can read multiple items in a single pass, even if they’re in boxes or stacked on shelves. In practice, this means that counting a full pallet can happen without unpacking a single box.

Steps for Integration

- Choose the right tags: Think about your environment—metal shelves, moisture, or rough handling can affect performance. RFID Reader.io offers tags designed to withstand these conditions.

- Prepare your system: Make sure your inventory software can accept RFID input. Most modern WMS or POS systems support this.

- Place readers strategically: Handheld readers work for spot checks; fixed readers are better for entry points or high-traffic areas.

- Map the data: Each tag ID must correspond to a product record. Start small, test, and refine.

- Pilot the deployment: Begin with a single aisle or product category. Adjust placement, scan frequency, and tag orientation as needed.

- Full rollout and training: Train your staff in handling both readers and tagged items to ensure smooth daily operations.

Practical Benefits Observed

- Faster stock counts: What used to take hours is now a few minutes.

- Fewer errors: Automated scanning eliminates most human mistakes.

- Real-time updates: Stock levels are always current.

- Scalable: Adding new products or warehouse zones is straightforward.

Using RFID Reader.io hardware and tags, the warehouse saw a clear reduction in labor hours and miscounts, freeing up employees for higher-value tasks.

FAQ – RFID Tag Integration

Q1: What are RFID tags?

Small electronic devices attached to products that transmit unique identifiers to RFID readers.

Q2: How do RFID tags improve inventory tracking?

They allow fast, bulk scanning and real-time updates, reducing errors compared to manual or barcode-based methods.

Q3: Can RFID tags work with existing inventory software?

Yes. RFID Reader.io tags integrate with most WMS, POS, and ERP systems.

Q4: Do RFID tags require line-of-sight?

No. They can be read through packaging, boxes, or shelves.

Q5: Are RFID tags durable for warehouses or retail?

Yes. RFID Reader.io provides tags resistant to moisture, metal interference, and rough handling.

Q6: How do I test RFID tag integration?

Start with a small batch, scan items with readers, and check data accuracy before full deployment.

Q7: Can RFID tags help with loss prevention?

Yes. They provide real-time tracking and alerts if items leave designated areas.

Q8: Are handheld or fixed readers better for integration?

It depends. Handheld readers are flexible; fixed readers are ideal for entry/exit points or high-traffic areas.

Send Us An Email

Feel free to send us an email and we will reply to you as soon as possible.