Global Trends in Fixed RFID Reader Deployment Across Industries

It’s interesting to see how something as invisible as radio waves is quietly reshaping how we manage things in the physical world. Fixed RFID readers used to be the kind of tech only large logistics companies talked about—big budgets, complex setups, lots of antennas. But in the last few years, that’s changed. Now you find them in hospital corridors, production lines, and even medium-sized distribution centers that never thought about automation before.

From my perspective, the growth isn’t really about the technology itself. It’s about visibility—companies finally want to see what’s happening across their operations in real time. Fixed RFID readers give them that, without asking people to scan every box or item by hand.

A Shift in How Companies Think About Tracking

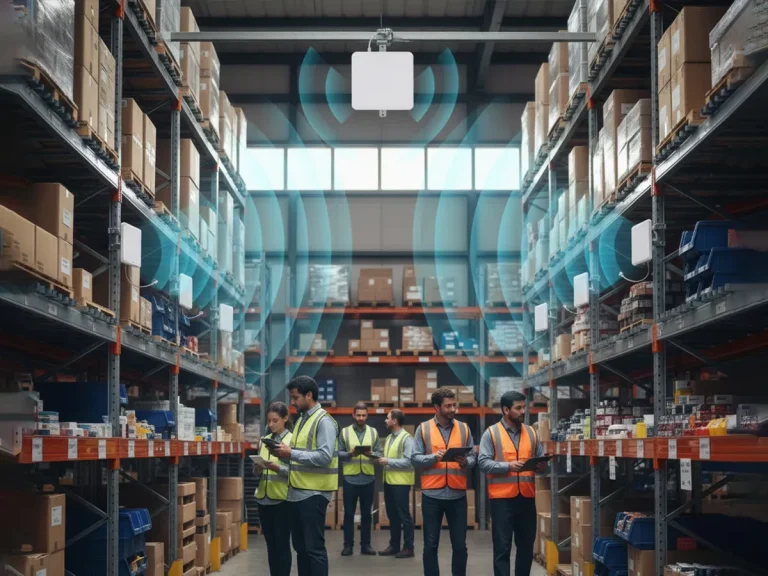

When you walk into a warehouse today, there’s a good chance the data you see on the management dashboard isn’t coming from manual entries. It’s streaming automatically from fixed RFID readers mounted near gates, conveyors, and storage racks.

These devices quietly detect thousands of tags every second. Unlike handheld readers, which need a person to move around, fixed readers sit in key points and build a continuous picture of item movement.

What’s driving adoption now? A few things stand out:

- Pressure for speed – E-commerce and just-in-time manufacturing leave no room for delays.

- Labor shortages – Automated reading reduces reliance on staff for repetitive scanning.

- System integration – Today’s RFID hardware connects easily into WMS and ERP systems.

- Falling costs – The price per reader has dropped as production scales up globally.

One of the engineers I spoke with recently mentioned how switching from handheld to fixed readers cut their manual scan time by nearly 70%. That’s the kind of quiet improvement that keeps spreading.

From Warehouses to Hospitals

If you think RFID is only about boxes and pallets, it’s time to look closer. Hospitals and laboratories have become big adopters of fixed RFID readers too.

In healthcare, the technology isn’t just about logistics—it’s about trust. Test samples, blood bags, and critical equipment are all tagged, and fixed readers ensure nothing gets misplaced or expires unnoticed. What used to require three manual checks now happens automatically in seconds.

Even smaller labs are catching on. The rise of compact, network-friendly readers means installations no longer require complex cabling or high-end IT infrastructure.

How Global Deployment Is Taking Shape

Asia-Pacific leads the way right now. Manufacturing powerhouses in China, Korea, and Japan are investing heavily in RFID-enabled production lines. Europe is catching up, particularly in industries with strong traceability standards—like pharmaceuticals and automotive.

North America is pushing hard on healthcare and retail, driven by cost-saving and security.

It’s not just about the number of devices deployed. It’s about how they’re used. A few years ago, many companies bought RFID hardware just to tick the innovation box. Now, they’re actually integrating it into core workflows—where it delivers measurable value.

Technical Trends You Can’t Ignore

If you’ve looked at the newest generation of fixed readers, you’ll notice they’re not just radio receivers anymore. They’ve started to include smarter features—local data processing, adaptive power control, and even AI-assisted filtering to reduce tag collisions.

In some cases, readers now perform basic analytics on-site before sending data to the cloud. This approach, sometimes called edge RFID, saves bandwidth and increases responsiveness.

Another interesting development is design: modern readers are smaller, better sealed, and easier to mount. They’re starting to blend into environments rather than stand out as industrial equipment.

At RFID Reader.io, we’ve seen this trend push customers toward compact but high-performance models—especially when they’re integrating systems across multiple locations.

Not Without Its Challenges

It’s worth mentioning that RFID still has practical challenges. Metal shelves, liquids, and reflective materials can distort signals. Installations in older facilities may struggle with cabling or interference.

Another issue is understanding data flow. Once thousands of tags start feeding data every second, companies realize they need to handle more than just hardware—they need software that makes sense of all that information.

The more experienced integrators have learned to treat fixed readers not as plug-and-play gadgets, but as part of a system that requires proper testing, calibration, and support.

What Comes Next

If you asked me what the next five years look like, I’d say fixed RFID readers will keep getting smarter and quieter. You won’t notice them working—but you’ll feel their presence in how smooth your operations run.

The real frontier is data intelligence: turning raw reads into actionable insights. When a reader not only detects a tag but also recognizes patterns—say, why a certain zone is slower or where items often get misplaced—that’s when RFID becomes more than identification; it becomes optimization.

It’s not hard to imagine these systems linking with AI-driven platforms that continuously adjust antenna power, zone coverage, and timing automatically. That’s the direction the industry is heading, and it’s an exciting one.

Closing Thoughts

The story of fixed RFID readers is, in a way, the story of modern logistics itself—quiet, connected, and constantly evolving.

What used to be a specialized technology is now becoming a common foundation for accurate, real-time visibility across industries.

Companies that approach RFID as part of a bigger strategy—rather than just another gadget—are the ones seeing the most success.

And as someone who’s worked closely with engineers and integrators through RFID Reader.io, it’s clear that the focus is shifting from “can it read tags?” to “can it help me see what’s really happening in my operation?”

That’s where the future lies.

💬 FAQ Section: Fixed RFID Reader Deployment

Q1: What makes fixed RFID readers different from handheld models?

Fixed readers operate continuously without human intervention. They’re installed at gateways, conveyors, or production zones and can track thousands of tagged items in real time. Handheld models, by contrast, depend on manual scanning and are better suited for smaller-scale or mobile operations.

Q2: Are fixed RFID readers difficult to integrate into existing systems?

Not anymore. Modern readers come with flexible APIs, network interfaces, and open protocols that connect easily with warehouse management or ERP systems. Many integrators use middleware platforms—like those supported by RFID Reader.io—to simplify data synchronization across software layers.

Q3: What are the most common challenges during RFID deployment?

The main hurdles usually involve signal interference from metals or liquids, incorrect antenna placement, or inconsistent tag orientation. Each site has unique environmental conditions, so testing and calibration are essential before full deployment. That’s why professional setup support is still highly recommended.

Q4: Which industries benefit most from fixed RFID readers right now?

Manufacturing, logistics, retail, and healthcare lead the way. Hospitals use them for asset tracking and patient safety; logistics firms for real-time inventory movement; factories for process automation and traceability. The technology’s adaptability means even small businesses can scale into RFID gradually.

Q5: How does RFID Reader.io fit into this growing ecosystem?

RFID Reader.io focuses on providing accessible, standards-compliant fixed readers and integration tools for developers and system builders. Instead of just selling devices, the platform emphasizes interoperability—helping partners create smarter environments for tracking, automation, and data-driven decision-making.

Q6: What’s the future direction for fixed RFID technology?

Expect more intelligence at the edge. Future readers will process and filter data locally, reducing cloud dependence and improving speed. Combined with AI-driven analytics, this will make RFID not just a tracking technology—but a foundation for real-time operational intelligence.

Send Us An Email

Feel free to send us an email and we will reply to you as soon as possible.