RFID Warehousing Solutions

Application object: warehousing/warehouse of small and medium-sized enterprises

Application scenarios: manufacturing warehouses, auto parts warehouses, hardware wholesale warehouses, e-commerce and retail enterprise warehouses, medical equipment and pharmaceutical warehouses, power material warehouses, engineering construction material warehouses, food processing enterprise raw material warehouses, beverage and alcohol distribution warehouses, etc.

1. Industry Pain Points

In traditional warehouse management, manual record-keeping and barcode scanning remain the mainstream, but they present the following challenges:

Low inbound/outbound efficiency: Manual scanning of each box of goods requires scanning one by one, which is time-consuming and labor-intensive.

Large inventory errors: Manual inventory is prone to missed or incorrect scans, resulting in discrepancies between inventory and actuals.

Difficulty locating goods: Large piles of goods and a large number of SKUs result in high search costs.

High labor costs: With rising labor costs, SMEs are increasingly looking to automation to reduce costs and increase efficiency.

These issues limit warehouse efficiency and impact the customer delivery experience.

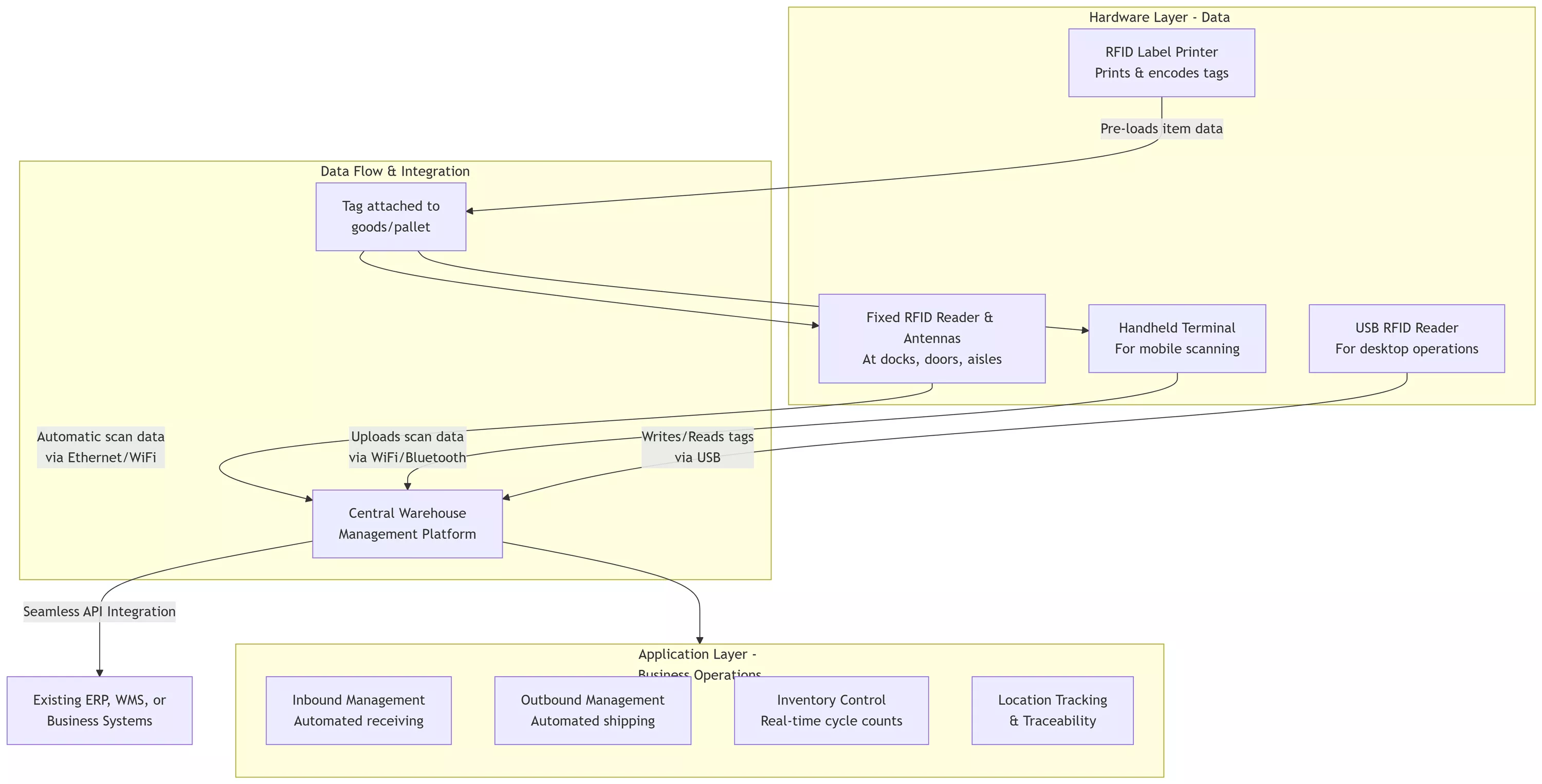

2. Our RFID Solutions

We offer a lightweight RFID smart warehousing solution. Combining an RFID reader, RFID label printer, RFID antenna, and handheld terminal, we achieve:

Quick batch labeling of incoming goods

Fixed RFID readers at entrances and exits enable automatic data collection

During inventory checks, RFID handheld terminals can quickly scan thousands of items

USB RFID readers allow desktop label writing and data management in the office

The RFID label printer can generate customized labels on the fly, adapting to different goods materials and environments

Streamlined process: Labeling → Incoming goods collection → Outgoing goods identification → Inventory check → Data upload to ERP

3. Recommended Product Portfolio

Fixed RFID Reader

(1) Suitable for warehouse doors and sorting ports

(2) Supports multi-antenna access and wide coverage

USB RFID Reader

(1) For office writing, testing, and desktop identification

(2) Simple plug-and-play

RFID Handheld Terminal/Bluetooth Reader

(1) Suitable for inventory and mobile inspections

(2) Supports Wi-Fi/Bluetooth data synchronization

RFID Antenna

(1) Meets wide-range reading requirements

(2) Installed at entrances and exits, and in warehouse aisles

RFID Label Printer

(1) Instantly prints readable and writable labels

(2) Supports barcode + RFID hybrid printing

RFID tags (Multiple Specifications)

(1) Available in paper, waterproof, metal-resistant, and high-temperature resistant versions

(2) Meets the needs of different cargo packaging and environments

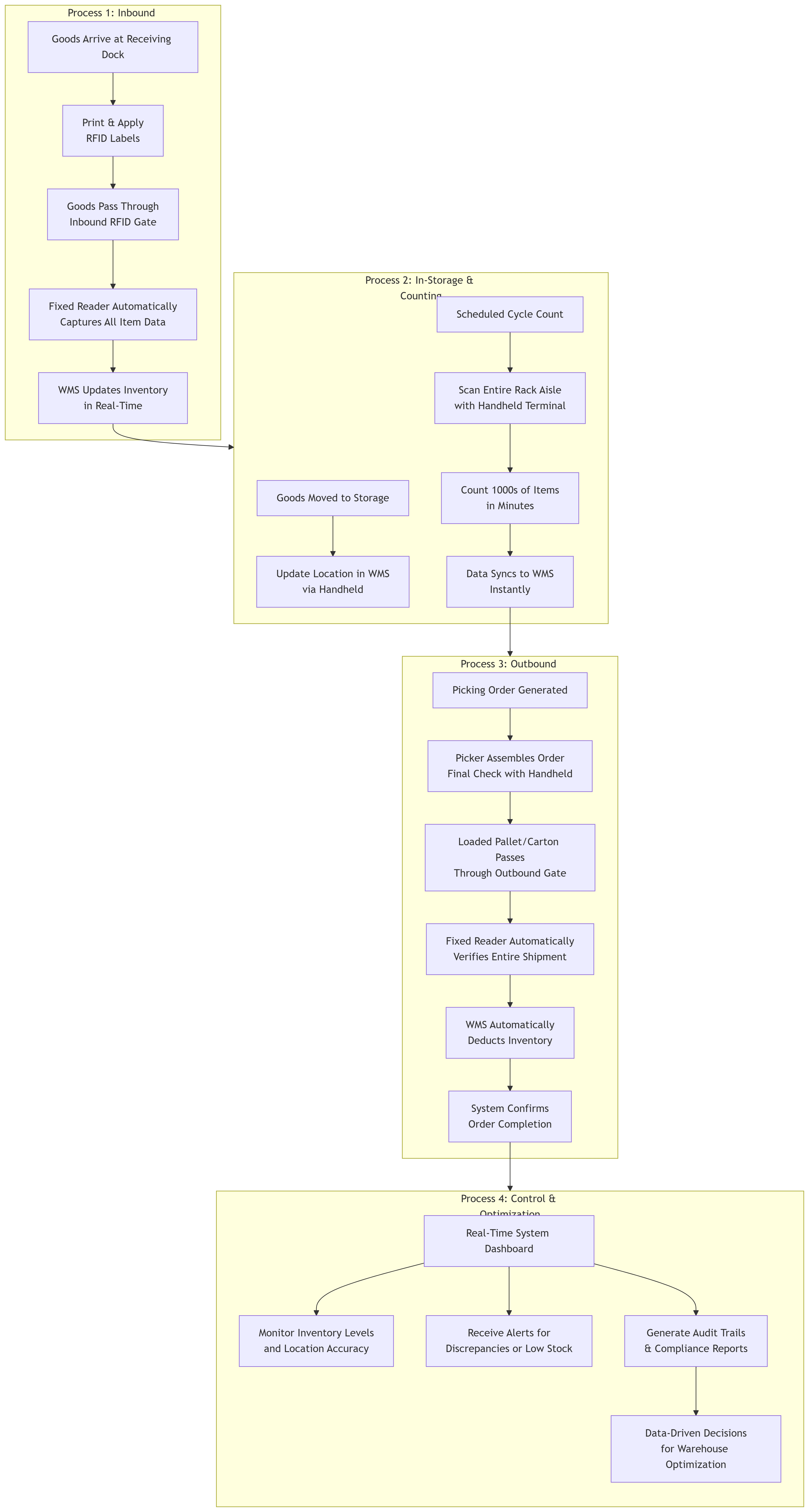

4. Management Process

Inbound Management

Goods arrive at the warehouse → Print labels → Fixed readers automatically capture data → Upload to the system

Outbound Management

Deploy antennas at loading ports → Automatically identify outbound goods → Reduce manual inventory

Inventory Counting

Scan with a handheld terminal → Count thousands of items in 30 minutes → Real-time data updates

Abnormal Tracking

In the event of lost or faulty goods → System quickly locates the location → Accountability is easily traced

5. Customer Value

Low-cost entry: Lightweight equipment, suitable for small and medium-sized warehouses

Quick deployment: No major IT upgrade required, supports ERP integration

Flexible combination: Freely combine Fixed RFID readers, handheld terminal, USB readers, and label printers

Contact us for a quote on our RFID Warehousing Kit